Turnkey Packaged Drinking Water Projects

We Ultracare group is one of the leading turnkey solutions provider of Packaged Drinking water Plant. We are manufacturer and supplier for all machineries and set up as BIS standards for Packaged Drinking water plant.

Setting up a packaged drinking water plant involves many challenges, lack of expertise and unavailability of market information. But with Ultracare, you just need not worry. Our professionals are well trained and groomed at assigning all your challenges from financing, plant erection, BIS inspections till design and banding of final product.

Operating a bottling plant is a bigger task than setting it up. Most projects cannot get off the ground because of lack of support and compliance with standard norms. But, with Ultracare, bring yourself wealth of knowledge that ensures complete compliances with BIS norms.

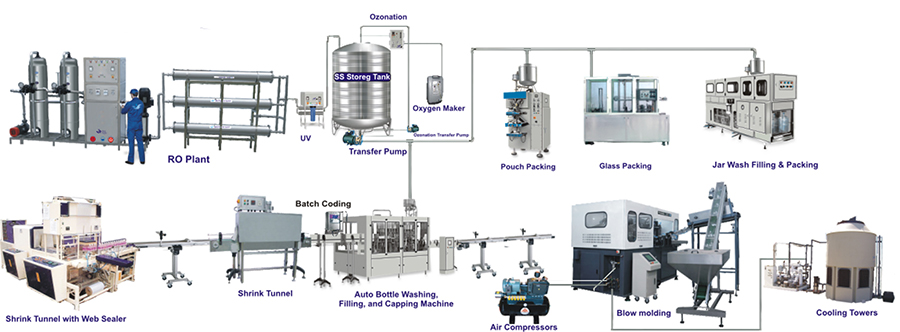

turnkey solution for pdwp includes:

- Pre-Projects consultancy

- Location & raw water source auditing

- Selection, supply & Erection of Machineries

- BIS inspection and licensing

- Product design

- Resources and training

- Support & services

We are remarkable entity, engaged in offering high quality Turnkey Project For Bottling Plants. We have expertise in drinking water supply, treatment, and distribution. Advanced processing equipments and construction team, a flexible management experience that we behold, we offer excellent product quality and service to customers. The company is well equipped with technology research and development center, engineering design team, equipment manufacturing organization, installation team, training and service team.

We have spread our skyline, in various turnkey projects which we have successfully executed. We have efficiently rolled out high capacity projects at multiple locations in India, making us a trusted turnkey solution provider for Packaged Drinking Water plants.

Ultracare possess good information about the market, and knows a great deal of information about the wide range of potential customers. This information will be used to generate strategies, that will allow it to better understand its customers, their specific needs, and the most effective ways to communicate with them.

Our service plan includes:

- Exploring location for the plant

- Site Audit

- Water Resource Identification

- Plant Design

- BIS Inspection Support

- Commissioning and Packaging

- Product Launch

- Market Promotion And Distribution

We ensure that utmost attention is given while designing and manufacturing water purification plant. Which complete BIS norm and standard and fulfil potable water output quality. A 1- step purification to ensure that the product water get free of chemical and reach in nutritional value.

Capacity: 1000 LPH to 30000 LPH

MOC: Fully Stainless Steel / Semi Stainless Steel

Operation: Fully Auto /Semi Auto

Purification Stages: 10

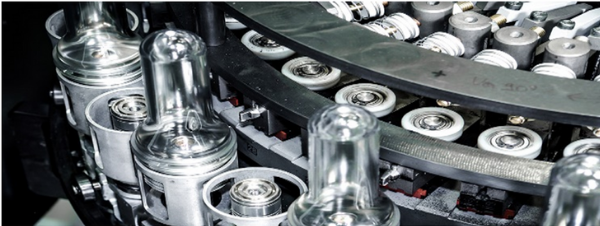

One of the important machinery in bottled water plant, we manufacture supply and install as per project requirement

How It work:

Rinsing: The rinser nozzles work under positive pump pressure. The rinser work on no-bottled no-rinse principal. The important feature to save water while rinsing bottle.

Filler: The filling valves work on the gravity principle, the water supplied to filling tank by centrifugal pump and water level control by controller. If the bottle is not deliver the valve does not work. Water will fill in the bottled by pre-set level/volume.

Capping: The cap is picked up by the chuck and firmly tightened onto the bottled neck. The capping chunks are finest quality precision component. The cap chute has a built in cap washing system. The cap will not be picked up if there is no bottled hence there will be no wastage of caps.

Capacity: 40 BPM to 300 BPM

MOC:Stainless Steel

Operation: Fully Auto

The wrap around hot melt labelling machine is a high speed system ideal for round bottles. It matched with filling machine and the conveyor connection both is synchronized to ensure smooth flow of bottles. Label cut with +-1 mm of the print mark. label cutter is PLC controlled. If there are no bottles on the conveyor, the label will not be deliver to the drum.

Capacity: 40 BPM to 300 BPM

MOC: Stainless Steel

Operation: Fully Auto

We supply Fully/semi auto pet stretch Blow molding machine with latest cutting edge technology to fulfill smooth production.

Capacity: 20 BPH to 120 BPH

MOC: Fully / Semi Stainless Steel

Technology: Hydraulic

Selection and supply of right compressor which fulfil plant air requirement uninterrupted round the clock. One of most delegate machinery in Drinking water bottling plant hence need appropriate consultancy.

Capacity: 60 CPM to 300 CPM

Operation: Fully Auto

Auxiliary: Air Dryer /Water chiller /Cooling Tower

Shrink Wrapping machines are able to pack in various size of water bottles. By using this machine in your production line you’re not only saving on packaging cost but you save one manpower cost also. Shrink Wrapping cases are very convenient to transport specially in rainy season.

Capacity: 200 TO 300 BPH

Operation: Auto /Semi Auto

MOC: MS-PC

We are having expertise in to setup state of the art in house laboratories for bottling plant since last two decades. Water testing laboratories is most important set up in water bottling plant. We do supply, set up and calibrate laboratories as per BIS standards.

Lab Type: Microbiological/Chemical

Standard: IS:14543 (For Packaged Drinking water)